Aplication

The burn-resistant metal mesh conveyor belt is widely used in metallurgy, cement, foundry, chemical industry and other fields to transport materials. It can be used as high temperature resistant, burning resistant conveyor belt, tear resistant conveyor belt, electronic weighing belt, acid and alkali resistant oil type conveyor belt, etc.

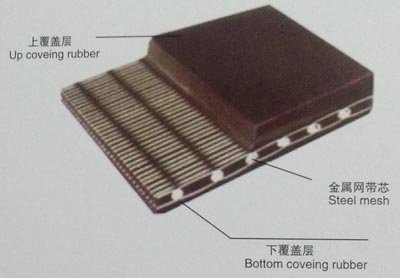

• The belt core adopts the metal spiral mesh integral belt core, which has excellent burning resistance, high temperature resistance, flame retardant, puncture resistance and tear resistance, and is the preferred object for tear-resistant conveyor belts;

• The metal mesh core acid, alkali and oil resistant conveyor belt joint has the same life as the belt body, and the conveyor belt should be preferred. The joint operation time is short and simple. Among them, the conveyor belt lifting belt and the metal mesh core high temperature conveyor belt are used at a temperature of 150℃-200℃;

• The temperature of the metal mesh core burning resistant conveyor belt is 200℃-800℃;

• Metal mesh core conveyor belts have good performance at different temperatures. Metal mesh core electronic weighing belts and endless belts have the characteristics of no deviation, no extension, and no disconnection of joints. Conveyor belt suppliers are better than other annular belts;

• Metal mesh core tear-resistant conveyor belt has excellent puncture and tear resistance, and is the preferred object for tear-resistant conveyor belts;

• Metal mesh core acid, alkali and oil resistant conveyor belt joints have the same life as the belt body, and should be preferred.

Specification | SN400 | SN630 | SN800 | SN1000 | SN1125 | |

Longitudinal through-thickness tensile strength | 400 | 630 | 800 | 1000 | 1250 | |

Metal mesh core thickness | 5.5 | 5.5 | 7.0 | 8.0 | 9.0 | |

Recommended top cover thickness | 6 | 8 | 9 | 10 | 10 | |

Recommended lower cover thickness | 3 | 3 | 3 | 3 | 3 | |

Cover and Core Viscosity Strength (average value of longitudinal sample) | ℃ | ≥10N/mm | ||||

160℃ | ≥4.0N/mm | |||||

Conveyor Min. Roller Diameter mm | 150 | 200 | 300 | 400 | 500 | |

Tape width mm | 300-2800 | |||||

If you have any questions, feedback or comments, please fill out the form below and we will get back to you as soon as possible