Aplication

Our conveyor belt vulcanizer equipment is widely used in hot vulcanized joints and repairs of various conveyor belts in metallurgy, mines, cement plants, power plants, ports, building materials, chemicals and other industries.

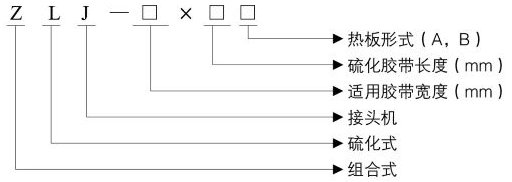

The combined conveyor belt joint vulcanizer produced by our company has the following characteristics:

Main frame, hot plate → high-strength aluminum alloy material (light weight, easy to carry on-site construction);

Heating method→electric heating (working power supply: 660V/380V, 50HZ) (heating block, stable, high thermal efficiency, small temperature difference of hot plate); pressurization method→water pressure type (using a new type of water bladder, which can provide 0-2MPa vulcanization pressure ) (balanced and stable pressure);

cooling method → natural cooling method and rapid water cooling method (water source can be ordinary tap water) (quick cooling hot plate, rapid cooling, saving vulcanization time; shortening from vulcanization temperature to 60 ℃ to 20 minutes );

Heating time → less than 40 minutes from normal temperature to vulcanization temperature of 145°C

Hot plate form → Type A (parallelogram, 72°); Type B (rectangular, 90°).

If you have any questions, feedback or comments, please fill out the form below and we will get back to you as soon as possible