Aplication

Large inclination sidewall conveyor belt are widely used in port, metallurgy, mining, electric power, coal, foundry, building materials, food, chemical and other fields of material transportation.

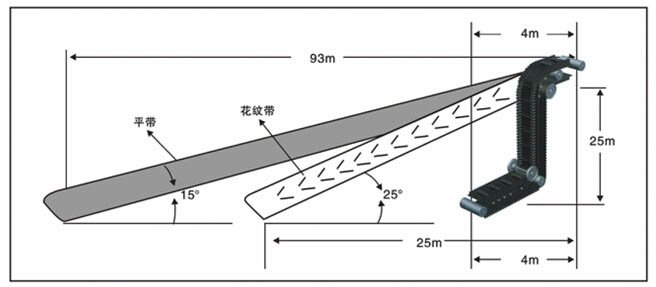

Features: It can continuously convey various bulk materials at any inclination angle of 0-90 degrees, from a small particle size to a large particle size of 400mm, and the conveying volume is from 1 cubic meter/hour to 6000 cubic meters/hour. It has the characteristics of large conveying inclination, wide application range, small footprint, no transfer point, reduced civil construction investment, low maintenance cost, large conveying capacity, etc., which solves the conveying angle that cannot be achieved by ordinary conveyor belts or patterned conveyor belts.

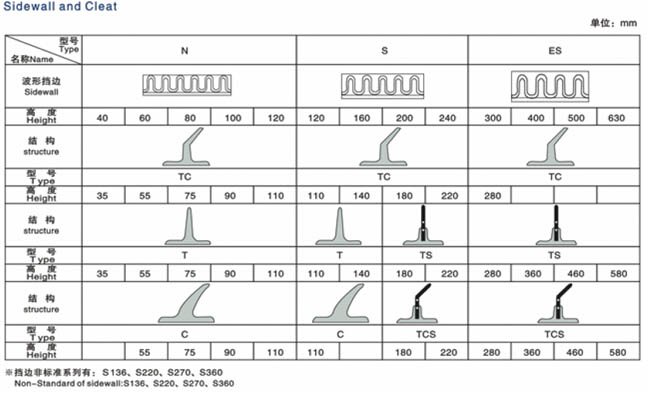

The diaphragm produced by the company is made of fiber composite material, which has high stiffness and enhanced impact resistance to avoid the deformation of the diaphragm due to stress. In the case of heavy wear, for easy maintenance, the diaphragm can be made into an embedded type, such as TS and TCS. When the inclination angle of the conveyor is less than 40 degrees, the diaphragms shall be T-type or TS-type; when the inclination angle is greater than 40 degrees, the diaphragms shall be C-type, TC-type or TCS-type.

When arranging the spacing of the diaphragms, the corresponding peaks of the corrugated ribs should be considered. In order to prevent the material from leaking from the two seams and the dead corner of the material accumulation when unloading. Our company produces corrugated sidewall conveyor belts. The sidewalls, diaphragms and base belts are bonded by secondary low-temperature hot vulcanization bonding. The bonding strength is high, the bonding is firm and smooth, and the board does not fall off or fall off. The helical connection between the diaphragm and the corrugated rib increases the overall rigidity and improves the performance, and solves the problem of material leakage.

The models of the formwork partitions can be divided into:

Corrugated rib and diaphragm combination table

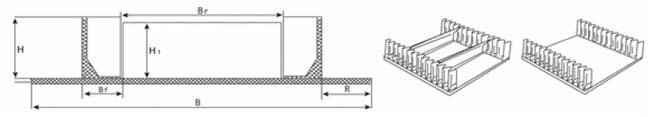

The corrugated sidewall conveyor belt requires certain tensile strength and wear resistance. Among them, for the corrugated sidewall conveyor belt with empty edges, in order to meet the requirements of angle reversal, the longitudinal direction of the belt requires flexibility, and the transverse direction requires a certain rigidity. The corrugated sidewall conveyor belt produced by the company adopts a transverse rigid base belt with a special structure, which solves the phenomenon of belt collapse during the return process of large-sized conveyor belts.

The base tape is composed of four parts: upper covering glue, lower covering glue; belt core and transverse rigid layer. The thickness of the upper covering glue is generally 4.5-8mm; the thickness of the lower covering glue is generally 1.5-4.5mm. The core material bears the tensile force, and its material can be cotton canvas (CC), nylon canvas (NN), polyester canvas (EP) or steel wire rope (ST). In order to increase the lateral rigidity of the baseband, a special reinforcement layer is added to the core, which is called lateral rigidity layer. The width specification of the baseband is the same as that of the ordinary tape, and conforms to the standard of GB7984-87.

The company has reformed and innovated the manufacturing process of the corrugated sidewall according to the principle of use of the corrugated sidewall belt, which has increased the service life of the sidewall. The S-shaped corrugated ribs can be divided into light (N), medium (S) and heavy (ES) according to the bearing capacity.

If you have any questions, feedback or comments, please fill out the form below and we will get back to you as soon as possible