Aplication

Our Nylon/polyester ordinary conveyor belt is widely used in material transportation in mining, port, coal, metallurgy, construction, chemical industry, grain and other fields.

Classification:

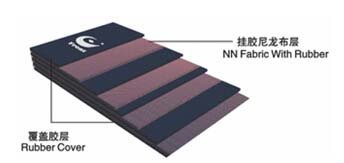

According to the different tensile layer materials, it is divided into: nylon (NN) conveyor belt, polyester (EP) conveyor belt, cotton canvas (CC) conveyor belt.

According to the difference of covering rubber: there are ordinary type, heat-resistant type, high-temperature-resistant type, burning-resistant type, wear-resistant type, heat-resistant wear type, general flame-retardant type, static-conductive type, acid-base-resistant type, oil-resistant type and so on.

Nylon (NN) conveyor belt: the belt has good elasticity, high strength, good impact resistance, good flexural resistance, good trough formation, and small elongation.

Polyester (EP) conveyor belt: high modulus of belt body, small elongation, good heat resistance, impact resistance, suitable for conveying materials under high load and high speed conditions in medium and long distances.

Cotton Canvas (CC) Conveyor Belt: A traditional conveyor belt, suitable for short to medium distance conveyor belts.

Selection knowledge:

Layered fabric core conveyor belt specification series

Tape Type | fabric model | Single layer fabric strength(N/mm) | Single layer fabric thickness(mm) | Cover glue thickness | Number of layers | width range(mm) | single roll length (m)/roll | |

Glue | glue down | |||||||

Nylon conveyor belt | NN100 | 100 | 0.70 | 3.0 4.5 6.0

| 1.5 3.0 6.0

| 2-10 | 300-2200 | 20-200 |

NN150 | 150 | 0.75 | ||||||

NN200 | 200 | 0.90 | ||||||

NN250 | 250 | 1.15 | ||||||

NN300 | 300 | 1.25 | ||||||

NN400 | 400 | 1.50 | ||||||

polyester conveyor belt | EP100 | 100 | 0.75 | 2-8 | 300-2200 | 20-200 | ||

EP150 | 150 | 0.85 | ||||||

EP200 | 200 | 1.00 | ||||||

EP250 | 250 | 1.20 | ||||||

EP300 | 300 | 1.35 | ||||||

EP350 | 350 | 1.50 | ||||||

EP400 | 400 | 1.65 | ||||||

Cotton Canvas Conveyor Belt | CC-56 | 56 | 1.10 | 3-12 | 300-2200 | 20-200 | ||

normal type | It can transport powder, granular and bulk materials, and is used in the field of general material transportation. |

Oil resistant | With oil resistance, it is used for conveying oily materials. |

Acid and alkali resistant | It can transport acid and alkaline materials with a pH value of 4-10, and can withstand a certain concentration of hydrochloric acid, sulfuric acid, nitric acid, weak alkali and other materials |

heat resistant | Divided into (T1 type) resistant to temperature not more than 100 ℃, (T2 type) resistant to temperature not more than 125 ℃. |

High temperature type (burning resistance) | (T3 type) can withstand temperature not more than 150℃, high temperature resistant type can withstand temperature not more than 180℃, burning-resistant conveyor belt can transport materials with temperature of 200℃~600℃, used with metallurgy, coking, building materials and sintered products in foundry industries , cement clinker and various high temperature materials transportation. T3≤150℃, T4≤180℃, Fire Resistant: 200--600℃ |

flame retardant | The surface of the conveyor belt has flame retardant properties, which can instantly extinguish the flame, and is suitable for conveying materials in the open air in severe cold areas. |

cold-resistant | The surface of the conveyor belt has cold resistance and can be used at temperatures above -40°C. It is suitable for conveying materials in the open air in severe cold areas. |

Wear-resistant | The surface of the conveyor belt is resistant to impact and material wear at the edges and corners, which is suitable for conveying hard materials and materials with sharp and hard edges. |

If you have any questions, feedback or comments, please fill out the form below and we will get back to you as soon as possible